Vertimill Ball Mill Disadvatanages

مجال التطبيق

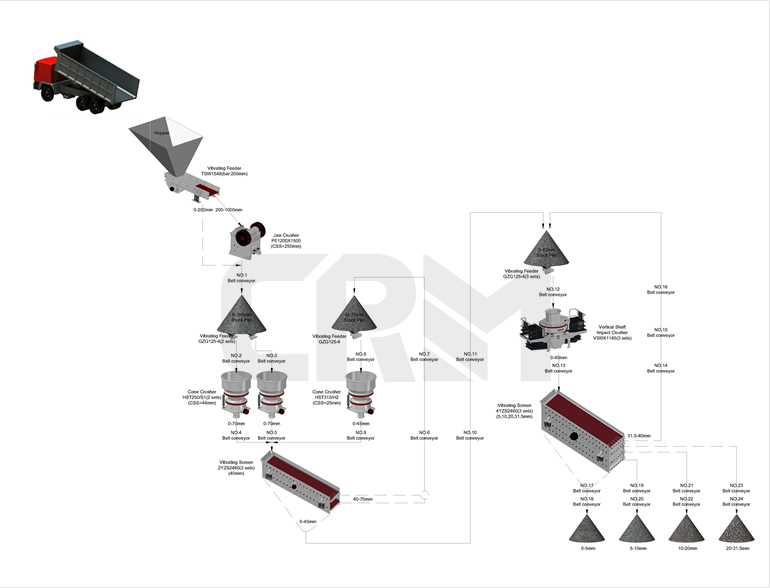

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

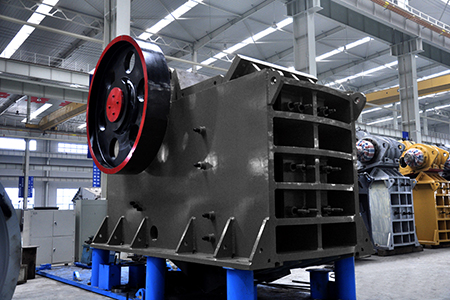

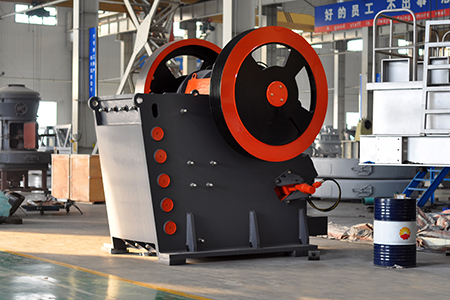

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

(PDF) Vertimill as the definitive step before

2019年4月8日 In the second staged development project, a Vertimill (VTM-1250-WB) regrind mill was selected to replace the existing conventional

VertiMill® – Preparing the feed within floatable regime at

2015年3月15日 Highlights. •. The VertiMill® is preparing the feed for flotation at lower specific energy. •. Successful application of stirred mill for secondary and tertiary grinding

Vertimill® - Metso

2022年7月13日 Vertimill® has proven to be a versatile tool that ex-hibits many advantages over traditional ball milling in various applications. It is capable of handling a wide range

DESIGN AND OPERATION OF VERTIMILL® FOR

2004年1月1日 The data also showed that the grinding circuit (with a Vertimill for secondary grinding duty) is more energy efficient than a conventional circuit that has a ball mill for secondary grinding...

DESIGN AND OPERATION OF VERTIMILL FOR

2023年10月23日 A laboratory ball mill, (D x L = 0.2 x 0.26 m at 75 rpm (approximately 80% of critical speed)) was used with a charge of 11 kg of balls. Three ball charges with

VertiMill® Performance Updates in Secondary and

2020年6月22日 If, subsequently, additional grinding power is required by a circuit to meet targeted concentrate production, this can lead to dificult decisions regarding the

APPLICATIONS OF VERTIMILL IN GRINDING CIRCUITS

2023年5月9日 The paper briefly describes the operation of the Vertimill, recent regrind applications in processing Iron ores where the impact of lower energy and grinding media

Vertical stirred mill scale-up and simulation: Model

2017年4月1日 According to Mazzinghy et al. (2015a), the parameter S1 E, obtained from the batch tests using a tube mill, shall be multiplied by a factor of 1.35 in order to get a

Vertimill® - Metso

2022年7月13日 the same application a Vertimill® has 50% less foot-print than a ball mill. Lower operating cost Vertimill® is an energy efficient grinding machine. They tend to grind more efficiently than, for ex-ample, ball mills with feeds as coarse as 6 mm to products finer than 10 microns. This provides up to a 40% higher energy efficiency.

sbm/sbm ball mills vertimill.md at master - sbm

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Vertical mill - Vertimill® 7000 - Metso

In fact, in the same application a Vertimill® has 50% less footprint than a ball mill. Lower operating cost Vertimill® is an energy efficient grinding machine. They tend to grind more efficiently than for example ball mills

Maintaining your Vertimill® - Metso

2018年8月1日 Maintaining your Vertimill®. Vertimills offer a range of benefits over traditional ball mills including higher energy efficiency, lower media consumption, reduced maintenance, longer wear life and a smaller footprint. However, Vertimills run into their own challenges in the field in terms of managing wear life as well as maintenance and parts ...

VERTIMILL® Lime Slaker Technical Sheet and Questionnaire

VERTIMILL® Lime Slaker Metso draws from more than 100 years of mill design and manufacturing expertise and three decades of successful VERTIMILL® applications. The VERTIMILL® is an energy efficient and cost saving alternative to tumbling mills and paste or detention type lime slakers. ... Metso Ball Mills Brochure. 3 Pages. Metso QdX4TM Mill ...

Metso’s energy-efficient Vertimill just got bigger: over 50

2024年4月17日 With over 500 installations worldwide, the Vertimill ® has proved to be a reliable grinding solution,” notes Davey. Vertimill ® grinding mills are part of Metso’s Planet Positive offering and provide up to 40% better energy efficiency than ball mills. The robust and vertical design benefits customers through long component lifetimes and ...

高岭土的深加工及开发应用现状

vertimill ball mill disadvatanages. Vertimill Grinding Disadvantages ginadevelopers Coarse Ball Mill Appliions Using The Vertimill vertimill ball mill disadvatanages disadvantages of a vertimill MTM Crusher Gypsum fine grinding powder Manufacturer Of Highend Gypsum Powder Khushi Minerals fine gypsum white powder, Wholesale Various High Quality ...

mill regrind vertimil

Vertimill Grinding Mills, A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing industrial appli ion of ball mill . Chat. Get Price Vertimill Mill (Grinding) Materials. VERTIMILL Grinding Mills 2011. CHN Lead Zinc Mine. Design Manual. conveyor belt design. Regrinding ball mill Mine Equipments

Vertimill® efficient especially in secondary and tertiary

2024年1月11日 Vertimill® requires a simple and small foundation, which means less floor space is required. In fact, in the same application a Vertimill® has 50% less footprint than a ball mill. Lower operating cost Vertimill® is an energy efficient grinding machine. They tend to grind more efficiently than, for example, ball mills with feeds as coarse as ...

sbm/sbm vertimill grinding plant.md at master - sbm

Vertimill VS Ball Mill To participate in the 911Metallurgist Forums,be sure to JOIN LOGIN Use Add New Topic to ask a New Question Discussion about Grinding.OR Select a Topic that Interests you.Use Add Reply = to Reply Participate in a Topic Discussion (most frequent).Using Add Reply allows you to Attach Images or PDF files and provide a more ...

VertiMill® – Preparing the feed within floatable regime at

2015年3月15日 The Metso VERTIMILL® (VTM) is a low intensity stirred mill with a tip speed of 3 m/s. These have been installed in a wide range of secondary, tertiary and regrinding duties receiving feed from AG, SAG and ball mills. More than 400 VertiMill® have been installed globally with total installed power of 227 MW.

Stirred mills - Metso global website - Metso

2022年7月12日 Stirred mills - Metso global website - Metso

Metso boosts stirred mill line-up with new high power giant

2024年4月17日 One Vertimill® 7000 grinding mill replaces the need for multiple smaller stirred mills to achieve the same power output. “The Metso Vertimill® 7000 features the same high energy efficiency as the previous models, but with over 50% more power. In addition, it is equipped with double door access, so less space is needed to open the doors.

The Metso VERTIMILL Jar Mill Test has Arrived - GSL

The GSL laboratory has received its latest piece of comminution testing equipment. The Metso VERTIMILL Jar Mill test mill arrived at the laboratory last week. The mill will now be commissioned using a Metso standard, the results of which will be verified by Metso. The mill allows GSL to offer VERTIMILL grindability studies, used for the sizing ...

VertiMill® – Preparing the feed within floatable regime at

2015年3月15日 The Metso VERTIMILL® (VTM) is a low intensity stirred mill with a tip speed of 3 m/s. These have been installed in a wide range of secondary, tertiary and regrinding duties receiving feed from AG, SAG and ball mills. More than 400 VertiMill® have been installed globally with total installed power of 227 MW.

Mills (VERTIMILL, ball mills, rod mills, AG SAG mills) - MCES

The Vertimill is a unique product offered exclusively by Metso, which has a long history in the mining industry. Mechanically, the Vertimill is a very simple machine with a mixing auger suspended in the chopping chamber, supported by spherical roller bearings and driven by a fixed speed electric motor via a planetary gearbox.

مطحنة الكرة vertimill disadvatanages

تستخدم Vertimills Mining Pedia The Free Encyclopedia draws from more than 100 years of mill design and manufacturing expertise, and over three decades of successful vertimill Figure 7 Vertimill pilot plant,2011 A ball mill 483mm x 908mm equipped with a feed ...

PREDICTING THE PRODUCT PARTICLE SIZE

2024年4月1日 The Colorado School of Mines offers courses in chemistry, geology, and physics, with a focus on mining geology and astroparticle physics.

TowerMill Ò (Eirich courtesy) and Vertimill™ (Metso courtesy).

The Vertimill™, manufactured by Metso has basically the same principle of operation and was intro- duced in the 1990's (Kalra, 1999). ... The ball mill was run for seven time intervals, ranging ...

سابق: الخطابة الفك محطم

التالي: شکن Giling آسیاب باتو

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت